More Nuts’ Stories

by Stéphane Pennequin

Here are a few more nuts' titbits for the real cognoscenti!

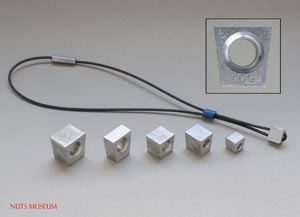

Drilled Out Nuts:After twenty years of research, I am truly delighted to finally be able to complete the Nuts Museum with such an awesome range of drilled out machine nuts, from the tiniest samples to the oversized ones. I already had several samples of drilled out machine nuts, some of them as intriguing as the ones machined by Harry Smith, but none of these historical nuts were still threaded with their original rope. In addition to those already threaded onto rope, John Cheesmond also offered a number of big drilled out machine nuts to the Nuts Museum.

For two years in the mid '60s John Cheesmond worked at an outdoor centre in Derbyshire where Joe Brown also worked and recall one of the weekend instructors (sadly, John can't remember his name maybe later?!) drilling out some engineering nuts for both Joe and him which they strung on to nylon slings and tapes.

That type of 'hawser laid' rope was the normal type of rope used by British climbers during the fifties and well into the sixties, with the red version with the nuts having been 'home dyed' to distinguish it from that of others. The thinner cord was known as 'line' and the thicker as 'three-quarter weight', even though there were 2 thicknesses above that. Three-quarter weight (approximately 850kg breaking strain the manufacturers claimed) was often used as a 90 metre double rope for those who went onto harder routes, or those who aided their way up 'artificial climbs' with pitons, étriers, wooden wedges and so on. That weight of rope was not pleasant to use on long rappels, particularly if one's clothing was thin!

A new edition to the Nuts Museum is an Acorn (the smallest size)! This Acorn is in good condition and complete, with its long "hawser" laid rope and the machine nut. In the early sixties British climbers used to carry their nuts around their neck. This Acorn belonged to Hank Harrison, of the Summit Club, with whom John Brailsford did the East Face of the Grépon in the early 1960s.

After some further research, I came to the following conclusion: in fact there are, to my knowledge, three generations of Acorns: -

The original Acorn on rope sling. Made from 1961 by John Brailsford in three sizes (3/4", 1", 1 ¼") with a machine nut (1/2") on the top of the chock, and marketed in the Roger Turner Mountain Sports shop (Nottingham).

Roger Turner Mountain Sports. Small Acorn on stitched tape sling or on wire; made by Paul Seddon (Parba) but not wired by himself, in 1969.

Large Acorn on 7mm Perlon rope, unknown manufacturer.

Clogwyn Climbing Gear. Acorn wiresling nuts (1971), made in three sizes:

n°1 (wire Ø 2,5mm)

n°2 (wire Ø 4mm)

n°3 (wire Ø 4mm)

The top of the nut is knurled.

In late 1963, members of Bruce Bedford's caving club – the Chelsea Speleological Society – were busy preparing for their 1964 expedition to Triglav Pothole in the Julian Alps. Having to be ready for a descent including a shaft of possibly up to 1,000ft deep, they made up a very large quantity of electron ladders (this was before the widespread use of SRT in caving).

Bruce Bedford and his companions were left with a quantity of steel wire, a Talurit press (on loan), and a quantity of ferrules for swaging. Up to that time, in rock climbing, they had used runners made from ordinary engineering nuts mounted on nylon cord. It occurred to them that steel wire would be much more convenient, and enable them to use smaller nuts, so they made a number of swaged steel wire runners for their personal use. That was in 1963.

After a treasure hunt, Bruce Bedford has managed to locate one of these original wire-mounted climbing nuts, in the possession of fellow club member George Fletcher, now generously donated to the Nuts Museum. This example was made in the latter part of 1963 or the very early part of 1964 by Pete Thompson who was another member of the caving club.

If the first recorded wire-mounted nuts were the Little Mesters made by Charles Curtis in 1961/1962, we can wonder if these nuts might be the very first ones with the wires swaged with the Talurit ferrule system…

Peck

Crackers were made from knurled round steel or Duralumin bar cut to the required length. The earliest ones, in which the wire ends were locked and silver soldered into a copper sleeve, were definitely in use in 1962. It was only in 1967 that the wires were swaged with the Talurit ferrule system. I do not have any exact dates for the nuts produced with such a system by Troll and Clogwyn Climbing Gear but, as these two companies were founded in 1964 and 1966 respectively, the original wire-mounted climbing nuts made by Bruce Bedford, at the Chelsea Speleological Society, could well be the very first ones.

Clog: After a very long research I have finally completed the Nuts Museum with a few more invaluable Clog old chocks: a full set of Hexagons and Wedges

with one hole (occasionally also known as Spuds )! Some twenty years ago, when I started to work seriously on the Nuts' Story , like me you may have thought that the Clog Hexagons would be the easiest chocks to find on the planet. Don't be disabused! The samples that I received in perfect condition are issued from the very first generation! They are rather crudely made, stamped with the old CLOG logo (without the ellipse), and mounted on coarse wire slings. These formidable guys were probably manufactured around 1967 or 1968… The size 6 was called Jumbo, the size 7, Mammoth !

I can only contemplate these treasures with a little nostalgia, travelling through time and remembering when Denny Moorhouse and Shirley Smith teamed up to set up the mythical company Clogwyn Climbing Gear in a derelict cinema hall of Deiniolen, in 1966; at that precise moment in time I would have liked to be a fly on the wall… I have also attached a short article published in the Western Mail Reporter in 1967; no doubt the climbing gear history buffs would very much enjoy reading such an historical document…

Parba

Big-Hs: From the beginning of my correspondence with Joseph Healy, it is no longer a secret that I now have a great belief in Father Christmas again. But now since opening Joseph's very precious package, I also believe in fairy tales… A few weeks ago, when I discovered an incredible set of Parba Big-Hs , in mint condition, on eBay, I spotted instantly that one size was missing but despite this I forwarded Joseph the link of this outstanding auction. The originator of Parba, Paul Seddon, has always told me that the original set consisted of ten different sizes. Paul even supplied me with a copy of the first invoice for Big-Hs . This historical document is dated 7th September 1968 , and the retailer was Frank Davies' The Climbers' Shop in Ambleside (English Lake District). During the past twenty years, in spite of a great deal of research, I was only able to lay my hands on two "somewhat poor" samples… To my knowledge, Paul Seddon has never stamped any size number on the Parba Big-H , so it was difficult to identify which my two sizes were, and which ones were missing, though a few smaller sets were numbered and marketed, when Paul Seddon teamed up with Tony Howard and Alan Waterhouse at Troll in 1970. As soon as I got home, I meticulously lined up the Big-Hs that Joseph sent on my desk and, feverishly, I compared my two samples with this little army. And… BINGO! The biggest of my very modest collection was in fact bigger than any of the original set, and it matched perfectly the nine samples, at the top end of its range! This BIG Big-H was given to me in November 1998 by the legendary climber… Joe Brown!

Here are two photographs of the Big-Hs

. I am wondering if such photographs of this full set would exist anywhere else…

Once again, I would like here to thank Joseph Healy for his immense generosity and for his unlimited interest in my work on the Nuts' Story. As a curator of the Nuts

Museum, I could not dream of a more attentive sponsor.

Two views of Parba Big-H nuts, now in the Nuts Museum collection!

Porter Nuts: Many climbers have played with stacked or opposed nuts for years. One of the first to improve on this idea was Charlie Porter. Sometime in the early 1970's Porter had a machine shop in Briceburg, downstream from the Yosemite Valley. He made his own aluminum stoppers, opposed them together on swaged cable loops and came up with adjustable sliding wedges. Porter sold these handy units to many climbers and some may still have them. Porter Nuts were also commercially available on a limited basis. On this photo only the size 5 (the biggest) is missing.

Porter Equipment #4, #5 and #6: These big guys, also made by the legendary climber Charlie Porter, are incredibly rare. The Nuts Museum has just acquired a full set.

Monkey Paws: John Middendorf, who set up A5, decided to part with a couple of his prototype Monkey Paws and contribute them to the Nuts Museum. The Monkey Paws were never made in production; John Middendorf made perhaps 30 prototypes and then a batch of 10 finished versions. It is a three-part sliding nut design using a ball and two grooved wedges that John Middendorf invented in 1987, and the concept predates that of the Ball-Nut or Lowe-Ball by 6 months! The Ball-Nut inventor, Steve Byrne, saw John's design, made and later patented his two-part version. The mangled and destroyed units in the picture were the results of strength testing using a hydraulic puller in the field. The fact that the cable broke as a result rather than the nuts pulling out shows the strength of the design.

John Middendorf has added some interesting notes about Monkey Paws on his website: bigwalls.substack.com. John hopes to clarify the story - it’s an old story, but he would prefer if Steve [Byrne] is credited specifically with Lowe Balls. He also discusses the design and hopes to inspire tinkerers to advance it, which he thinks possible, even though Totems solve most of this type placement.

Ball Races:

Ballrace (73 m, grade 17 [UK HVS, USA 5.9]) at Wirindi on Mount Piddington, climbed on 5th March 1965 by John Davis and David Witham, was the first known climb in Australia to use ball races for protection. As John Davis was part of the first ascent team of Balls Pyramid, a magnificent remote sea stack near Lord Howe Island, there is every chance that ball races were used in the first ascent of it too, which at 562 metres elevation, is a much more notable climb than Ballrace on Mount Piddington!

It was not an easy affair to lay hands on samples of this form of Australian climbing protection of that time. I believe that there is no mention of the use of ball races in the British climbing literature.

After long research, I first contacted John Davis about his ball races. John looked for them for the Nuts Museum, but so far he did not find them. He sent me a couple of pages from the book "Rope and Rucksack" he published in 1969, which shows the ones he was looking for.

I contacted Rod (Harding-Robbins) who mentioned the ball races on Chockstone Forum with most interesting comments on these historical pieces of Australian climbing gear:

"Ball races at the time, were usually the inner ring (often stronger than the outer ring), of bearings that fitted to shafts within mechanical applications.

Find an old gearbox, motor, etc, disassemble the race off a shaft, crack open the outer ring with a hammer, and you then had the ball bearings (useful for slingshots, or tom-bowlers in marble games!) plus the inner ring, that could be slung for pro, ... or also used as the retaining clip-point for a threaded swami seat style of harness.

They worked surprisingly well, though I did not like using any that had 'blued out', ie discoloured due to excessive heat from being seized on the shaft in an original application, as I considered them to be weaker!"

I would like to express here my gratitude to Rodney Kerr for parting with these invaluable ball races , as you wouldn't believe the rigmarole involved in posting items to France from Australia these days. Rod had to sign two different forms and show his drivers licence as ID... Good thing he was not posting me a bomb… or the "old fashioned" ball bearings , from within the shiny circular rings, as they may have been some Australian secret weapons… Therefore… it took seven months for Rodney's package to reach us in Corsica … It's probably an expression of the Australian way of life…

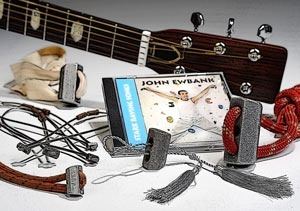

Ewbank Crackers: At the beginning of 2014, I received a mail from John Ewbank's partner, Fran Fleishman. I was very touched to receive such a message as I had only recently heard of John's passing away, a few weeks previously. A strange feeling dwelled within me as if I was still communicating with this exceptional man beyond the grave! Over a period of eight years, I was very fortunate to correspond with the legendary climber and he became a dear friend who would have loved to master the French language, this cemented very much our friendship. One of the most influential of Australian rock climbing scene, amidst a great deal of activities, John was the instigator of the first Australian climbing magazine,

Thrutch

, published the most excellent guidebook,

Rock Climbs in the Blue Mountains

, introduced the open-ended grading system, and championed the clean climbing ethic. To promote this philosophy, he even developed and marketed the Crackers that are still to this day cult chocks in Australia. Fran sent me photographs of several pieces that John had separated from his general hardware collection and kept apart as "precious". Among them, one amazing nut, slung on a silver string with two pompoms, which had John's name stamped on it! Fran very kindly parted with what therefore I, now, treasure to be John Ewbank's fetish Cracker…

Photos from top: Ewbank Crackers, Homage to John Ewbank including his CD

Stark Raving Songs

and the "Fetish Cracker",

Rock Climbs in the Blue Mountains

, and below, pages from

Rock Climbs in the Blue Mountains

.

Allow me to let John tell the story of the Crackers: "I suppose I should try to add that previous to the trip to Tasmania [1968], I had been making Crackers for about a year by renting bench space in a little engineering shop in Kings Cross [Sydney, New South Wales, Australia]. I then started a little workshop in the front room of the house in Surrey Hills [Victoria, Australia] and continued making Crackers in a few sizes until it slowly increased until they went from quarter inch swaged wire jobs all the way up to four and a half inch behemoths that could be used to kill a man with a single blow. Carrying the biggest ones almost guaranteed failure as a foregone conclusion. I should have called the biggest ones "The Kiss Of Death Series", despite all the lightening holes, the sheer weight of them made it virtually impossible for even the strongest leader to get off the ground at all, let alone progress upwards. In the end I was making twenty sizes [stamped JE with a size letter] and sending them all over Oz, as well as New Zealand and we even sent some to Honk Kong and South Africa. I started subbing the work out to an engineering shop in Redfern so I had time to climb again."

John moved to New York and began a new career as a singer-songwriter. One day he confessed to me that he felt far more passionate about his music than he ever was about climbing… A white lie if one considers the time and energy he put into opening all those routes in Aussie land! In the album

Stark Raving Songs

John sings "We're All Going To Croak". Fair enough John, but I failed to understand the urgency on this matter… The climbing community is as much grateful for your tremendous contribution as for your song "A Two Word Letter"…

After almost twenty years of research and many forlorn hopes, two of the three Forrest Mountaineering nut tools have finally landed in the Nuts Museum . To get them would not have been possible without Joseph Healy's invaluable interest and generosity in my work on the Nuts' Story.

The Bam Nut, "the Roll Royce of the nut tool", was developed by Forrest Mountaineering in the mid-seventies as a multi-purpose clean climbing tool which can be used for the placement and removal of nuts and slings, as a hammer, as a nut, or even as a cliff hanger. The aluminium head used as a nut fits nicely in a variety of placements in 1 ½" to 2 ¼" wide cracks. As a hammer head, it has just enough weight to drive and test pins. Heat treated chrome molybdenum steel is used in the pick/ handle with an aluminium alloy for the hex head. The two parts are force fitted together; a steel Spirol pin serves as a backup anchor.

Photos from top: Bam Nut and Crag Dagger, Bam Nut head, branding detail, the mythical Wire Nut Tool.

In 1980 Forrest made a slightly different version of the Bam Nut, the Crag Dagger, that came without the aluminium head. In 1993, Bill Forrest, with a lot of trust, kindly sent to Corsica his own climbing equipment on loan. It was not that easy for Bill to part with all these items as he was still an active climber, and this equipment was impossible to replace. Among these tools, there was a Wire Nut Tool . If I was able to take quite a good photograph of this very rare item but I had, of course, to send it back to Bill…

I had never seen this treasure again since that time, but after seeing this webpage, Bill very generously sent it to me once again… When once at home, Wire Nut Tool discovered the other members of the Forrest nut tool family, there was a great reunion on the shelves, and the party was wild…

Dave Rearick created his own chocks from wood of the Osage orange tree. Dave and George Hurley used them for the first all-wood ascent of Twister in 1973. Dave Rearick's " Plugs " as he called them were, though, very strong. He tested them thoroughly, and gave Pat Ament a full set, as a present, including his Clapper, an adjustable wooden nut for wide cracks. I am still working hard to get the design details and some good photos of the Clapper from Pat. I would like to remake an exact copy of this really interesting device for the Nuts Museum.

Bob Ryan tells that Dave Rearick gave him a set of six wooden nuts. Bob in turn has given these very rare nuts to me for the Nuts Museum a while ago. Bob also relates this anecdote: "I spoke with Dave, and he reminded me that I had taken a leader fall on the third pitch of Werk Supp. This was in May 1978. The nut jammed so that I had to return later with a tire iron to knock it out."

Let me tell you this fairy tale: while digging through Le Bon Coin on the Internet, I discovered without believing my eyes a Petzl Vérin à Diaclase (Petzl Screw Jack for Crack). The story of this mysterious device began for me a while ago. The French Mountain Guide and inventor of nuts, Dominique Thomas, sent me an old 1972 F. Petzl price list in October 2012. On the menu of the list a very enigmatic Vérin à Diaclase! But no photo or drawing of the tool. In my old Au Vieux Campeur catalogues, no mention either… A good friend of mine contacted Paul Petzl and was able to get good drawings from Petzl. From there, I now knew what a Vérin à Diaclase looked like... But no need to dream, to pray, to beg, Paul Petzl has only one sample of the treasure at the Petzl office.

I was able to purchase in extremis the “first hand” jack from a sympathetic and prolix seller of Le Bon Coin. Paul Petzl added some valuable information: first called Barre d’Expansion, 1966 for the date of manufacturing, and no more than 50 for the number of samples made! It seems that there have been two generations of this screw jack: the first has a limit of use painted in red; the second has a very clever internal safety stop.

Mainly used by cavers, fully deployed, with its two extensions and 91cm, the Vérin à Diaclase is, to my knowledge, the largest “artificial chockstone” ever made!

The very latest news concerning the Nuts Museum: after some twenty years of research, I have finally enhanced the collection with a very rare Charlet-Moser Grupp! From the historical point of view, this nut is really interesting. Only mentioned and pictured in an old article by Henri Agresti published in La Montagne et Alpinisme, in 1977, the Grupps were numbered from #1 to #4, the #4 being the smallest. They were the very first French nuts ever patented in 1973 (Patent FR 2.229.432). The inner composite wedge is probably made of nylon (polyamide 6.6).

If gathering all these treasures required a great deal of energy, patience and a strong sense of persuasion, this collection would not have been possible without the trust, faith and the shared passion of many generous donators.

While watching many of these sophisticated tools it looks like the time of the pocketful of stones is so far away and yet…